How Does The Friction Wheel Drive Of The Amusement Carnival Ride Work?

A mechanical transmission that transmits power and motion by using the friction between two or more wheels pressed against each other is called friction wheel transmission.

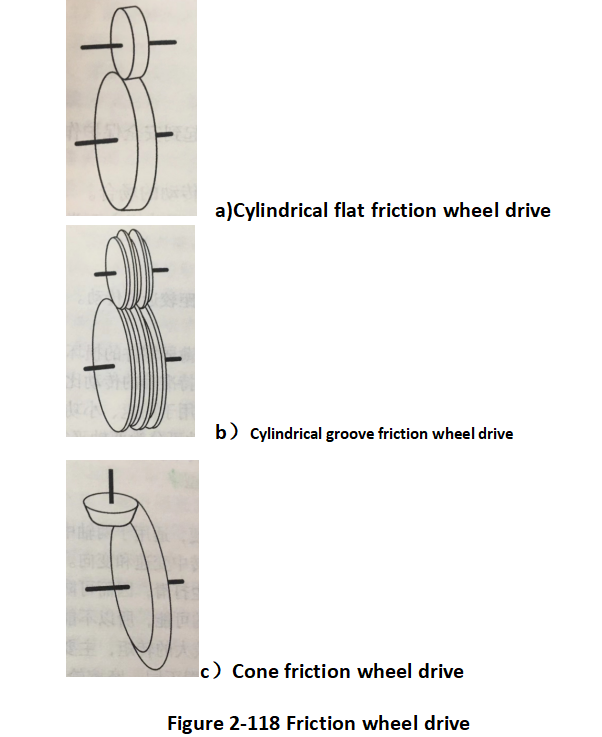

The friction wheel transmission of amusement equipment can be divided into two types: fixed transmission ratio transmission and variable transmission ratio transmission. The fixed transmission ratio friction wheel transmission with basically fixed transmission ratio is divided into three types:

cylindrical flat friction wheel transmission, cylindrical groove friction wheel transmission and conical friction wheel transmission, as shown in Figure 2-118. The first two types are used for transmission between two parallel shafts, and the latter type is used for transmission between two intersecting shafts.

When working, there must be enough pressing force between the friction wheels to avoid slippage and damage to the friction wheels and affect the normal transmission. Under the condition of the same radial pressure, the grooved friction wheel drive can generate larger friction force and has higher transmission capacity than the flat friction wheel, but the grooved wheel is easy to wear.

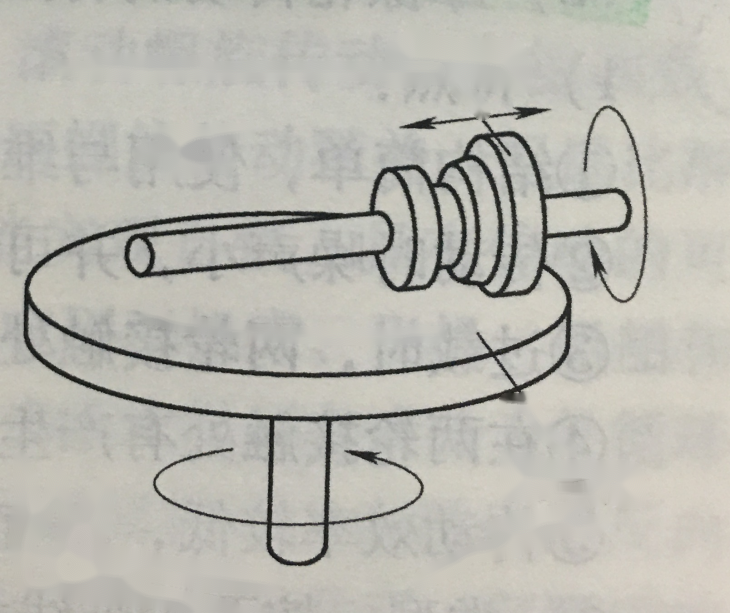

Variable transmission ratio friction wheel transmission is easy to achieve stepless speed change, and has a large speed adjustment range. The mechanical continuously variable transmission is shown in Figure 2-119. In the figure, when the driving wheel moves in the direction of the arrow, the rotational speed of the driven wheel changes continuously; when the driving wheel moves past the axis of the driven wheel, the driven wheel rotates in the opposite direction.

The friction wheel transmission structure is simple, the transmission is stable, the transmission ratio is easy to adjust, and it can cause slippage when overloaded to avoid damage to the device; but its transmission ratio is not large, the efficiency is low, the wear is large, and the force on the shaft is usually large, so it is mainly used for transmission. When the power is not large or the stepless speed regulation is required.Application range:amusement park、playground、theme park.

Figure 2-119 CVT

The main requirements for friction materials are good wear resistance, high friction factor and high contact fatigue strength. In high-speed, high-efficiency and compact-sized transmissions, the friction wheels are often made of hardened steel to hardened steel and run in oil. The dry friction transmission often uses cast iron to cast iron, steel to wood or cloth phenolic laminate, or the driven wheel surface is covered with a layer of leather, asbestos-based material or rubber.

The design of the friction wheel drive of the amusement equipment is mainly to calculate the pressing force according to the circular force to be transmitted. When metal is used as friction material, the contact stress of the working surface should be limited; when non-metal is used, the pressure on the unit contact line should be limited.