What is the working principle of friction wheel transmission in Carnival amusement park equipment

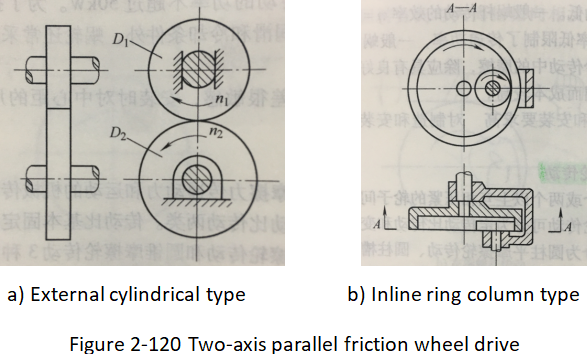

The Carnival amusement park equipment working principle of friction wheel transmission.Friction wheel transmission is a mechanical transmission that uses the friction force generated by the direct contact of two wheels to transmit motion and power.Figure 2-120a shows the simplest external cylindrical friction wheel drive, which consists of two cylindrical friction wheels pressed against each other.

During normal transmission, the driving wheel relies on the action of friction to drive the driven wheel to rotate, and ensures that there is enough friction at the contact point of the two wheel surfaces, so that the friction torque generated by the driving wheel is sufficient to overcome the resistance torque on the driven wheel.If the friction torque is less than the resistance torque, there will be a relative slip phenomenon in the transmission where the two wheel surfaces contact, which is called “slip”.Carnival amusement park equipment Application range:amusement park、playground、theme park.

There are two ways to increase the Carnival amusement park equipment friction force: one is to increase the positive pressure, and the other is to increase the Carnival amusement park equipment friction factor.To increase the positive pressure, a spring or other force-applying device can be installed on the friction wheel.

However, this will increase the load acting on the shaft and the bearing, resulting in an increase in the size of the transmission parts and making the mechanism bulky.Therefore, the Carnival amusement park equipment positive pressure can only be increased appropriately.

The Carnival amusement park equipment method of increasing the friction factor is usually to make one of the friction wheels with steel or cast iron material, and stick a layer of asbestos, leather, rubber cloth, plastic or fiber material on the working surface of the other friction wheel.The friction wheel with a soft wheel surface should be used as the driving wheel, which can avoid slippage during transmission, resulting in local wear on the wheel surface of the driven wheel and affecting the transmission quality.