What Is The Worm Drive Of Carnival Amusement Rides Accessories

Characteristics of worm drive

1) The transmission ratio is large. The worm drive, like the gear drive, can ensure an accurate transmission ratio, and a large transmission ratio can be obtained.

In gear transmission, in order to avoid undercut, the number of teeth of the pinion should not be too small, and the number of teeth of the large gear should not be too large due to the size of the transmission device, so the transmission ratio is limited.

In the worm drive, the number of heads of the worm is z1=1~4. When the number of teeth of the worm gear is small, z2, a single-stage transmission can obtain a large transmission ratio.

The worm pair used for power transmission usually has a transmission ratio of i=10~30; in general transmission, i=8~60; when used in an indexing mechanism, it can reach i=600~1000.

Such a large transmission ratio, such as gear transmission Then you need to use multi-stage transmission to get it. Therefore, when the transmission of amusement equipment is relatively large, the worm drive has the characteristics of compact structure.

Application range:amusement park、playground、theme park.

2) Smooth transmission and low noise. The tooth of the worm is a continuous helical surface, and the meshing with the worm gear is gradually entering and exiting during transmission.

The teeth of the worm gear basically slide along the helical surface, and the number of teeth meshing at the same time is large. The worm drive of amusement rides is more stable than the gear drive, with no impact and low noise.

3) It is easy to realize self-locking. Like the screw drive, when the lead angle of the worm is smaller than the equivalent friction angle of the worm pair material, the worm drive is self-locking.

At this time, only the worm gear can be driven by the worm, and the worm cannot be driven by the worm gear. This feature is used in mechanical equipment and can play the role of safety insurance.

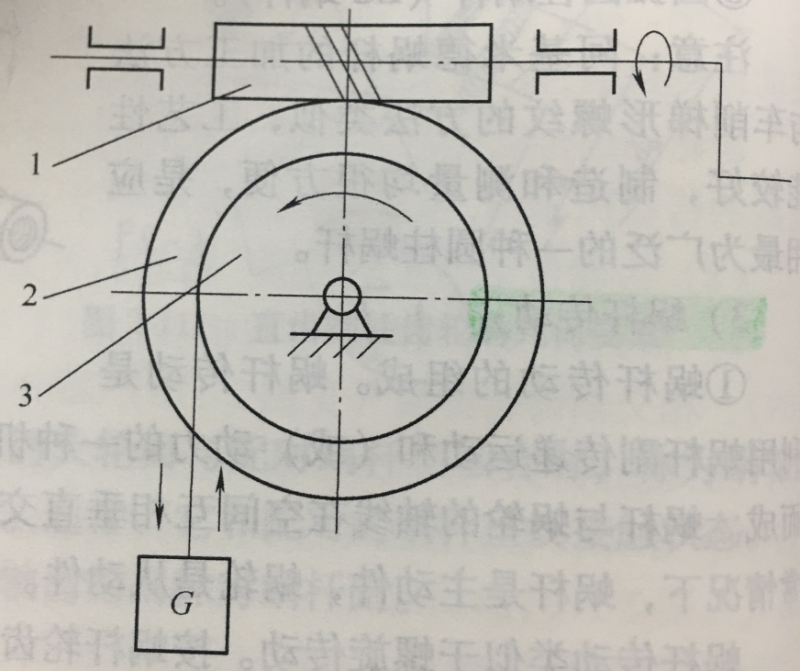

The manual lifting device shown in Figure 2-117 uses the self-locking characteristics of the worm to make the weight G stay at any position without falling automatically.

The lead angle of the single-head worm is small, generally γ<5°, and most of them are self-locking, while the multi-head worm increases the lead angle with the increase of the number of heads, and does not necessarily have the self-locking ability.

For example, elevators that use worm gears and worms often use multi-head worms in order to improve the transmission efficiency, which do not necessarily have self-locking ability.

Figure 2-117 The application of the self-locking rod

1-worm 2-worm gear 3-roll

4) Large carrying capacity. In the worm drive, the prime line of the indexing cylindrical surface of the worm gear is changed from a straight line to an arc line, so that the meshing between the worm and the worm gear is in line contact, and the number of teeth entering the meshing is more, so compared with the point-contact staggered shaft helical gear transmission. , the carrying capacity is large.

5) The transmission efficiency is low. When the worm is driven, the relative sliding speed of the meshing area is large, and the wear loss is large, so the transmission efficiency is lower than that of the gear transmission.

Generally, the efficiency of worm drive is 0.7~0.8, and the efficiency of self-locking worm drive is less than 0.5.

The low transmission efficiency limits the transmission power, and the power of the general worm drive does not exceed 50kW. In order to improve the efficiency of the worm transmission and reduce the friction in the transmission, in addition to having good lubrication and cooling conditions, the worm gear is often made of anti-friction materials such as bronze, so the cost is high.

6) High manufacturing and installation requirements are sensitive to manufacturing and installation errors, and require high dimensional accuracy of center distance during installation.