What Is The Mechanical Transmission Of China Amusement Park Equipment?

Working machines generally rely on the prime mover to supply a certain form of energy (mostly mechanical energy) to work. However, it is rare that the prime mover and the working machine are directly connected, and it is often necessary to add a transmission device between the two to transmit power or change the state of motion.

According to different working principles, transmission can be divided into two categories: mechanical transmission (transmission in which mechanical energy cannot be changed into another form of energy) and electric transmission (transmission in which mechanical energy is changed into electrical energy, or electrical energy is changed into mechanical energy).

In industrial production, mechanical transmission is one of the most basic transmission methods. When analyzing a machine, whether it is a lathe, an internal combustion engine or a hydraulic press, its working process actually includes the movement process of various mechanisms and components. For example, friction wheels, pulleys, gears, sprockets, screws and worms are often used to form various forms of transmission devices to transmit energy.

A mechanical device used to transmit motion and power is called a mechanical transmission. According to the way of transmitting motion and power, mechanical transmission can be divided into friction transmission, meshing transmission, hydraulic transmission and pneumatic transmission.

According to the contact mode of the moving auxiliary components, it can be divided into two types: direct contact transmission and transmission with intermediate flexible parts (belts, chains, etc.).Application range:amusement park、playground、theme park.

Only a few common transmission methods are introduced here.

1.China Amusement Park Equipment belt drive

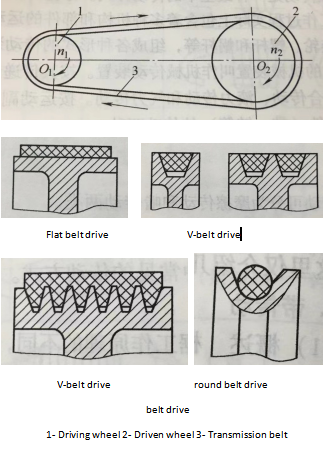

(1)Overview According to the different working principles, the belt drive can be divided into two types: friction drive and mesh drive. The working principle of the belt drive is to use the belt as an intermediate flexible member, relying on the friction or meshing between the belt and the pulley to transmit motion and (or) power.

As shown in Figure 2-100, tension one or several belts that are closed into a ring on the driving pulley and the driven pulley, so that the contact surface between the belt and the two pulleys generates positive pressure (or makes the synchronous belt and the two pulleys).

The teeth on the synchronous pulley mesh with each other), when the driving shaft O1 drives the driving wheel to rotate, relying on the friction between the contact surface of the belt and the two pulleys (or the meshing of the teeth), the driven wheel drives the driven shaft O2 to rotate. Realize the transmission of motion and (or) power between the two axes.

(2)China Amusement Park Equipment Main types and characteristics of belt drives

1)Friction belt drive. As shown in Figure 2-100, the cross section of the flat belt is a flat rectangle, and the inner surface is the working surface. The cross-section of the V-belt is an isosceles trapezoid, and the two sides are working surfaces. According to the force analysis of the wedge surface, under the conditions of the same pressing force and the same friction factor, the friction force generated by the V-belt is about 3 times larger than that of the flat belt.

So the V-belt has a strong transmission capacity, a more compact structure, and is the most suitable for application. widely. The cross section of the round belt is circular, and it is only used for small power transmission, such as sewing machines, instruments, etc. After the belt of friction belt drive works for a period of time, the initial tension will be reduced due to relaxation, and it needs to be re-tensioned to ensure the normal operation of the belt drive.

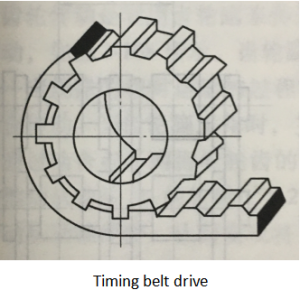

- Mesh belt drive. The meshing belt drive transmits power by meshing the teeth of the belt with the teeth on the pulley. A more typical synchronous belt drive is shown in Figure 2-101.