How To Do The Pre-Tightening And Anti-Loosening Of Threaded Connections For Outdoor Amusement Parks Ride?

Regarding outdoor amusement equipment, the threaded connection of the equipment must usually be tightened during assembly, so that the thread is subjected to a force before it is subjected to the working load. This force is called preload. For important connections, the preload of the threads should be neither too large nor too small. Because the size of the preload has a great influence on the reliability, strength and tightness of the threaded connection.

1) Preload of threaded connections. In fact, in the application of outdoor amusement equipment, most of the threaded joints must be tightened during assembly, so that the joints are subjected to force in advance before bearing the working load. This kind of threaded connection that requires preloading during assembly is called a tight connection. For important threaded connections, in order to ensure the assembly quality, special tools, such as torque spanners or constant torque spanners, are required during assembly to achieve the purpose of controlling the preload.

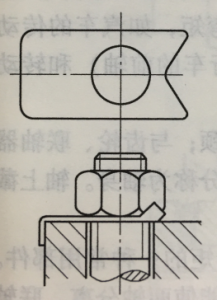

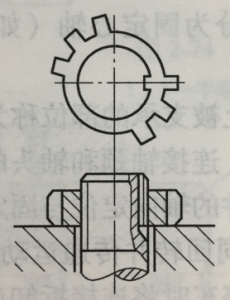

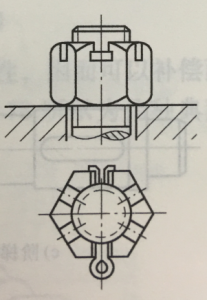

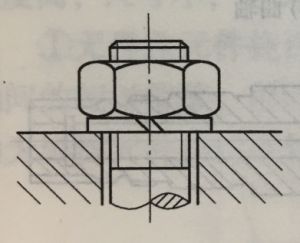

2) Anti-loosening of threaded connections. The basic principle of threaded joint anti-loosening is to prevent the relative rotation of the threaded pair. There are many ways to prevent loosening, and the commonly used methods are shown in Figure 2-70.

Figure 2-70 Common methods for preventing thread loosening

①Use friction to prevent loosening. The principle of using friction to prevent loosening is to generate positive pressure in the thread pair to form a friction force that prevents the thread pair from rotating relative to each other. This anti-loosening method is suitable for the connection of external static components of machinery, as well as occasions where anti-loosening requirements are not strict. Generally, a spring washer or a double nut can be used to prevent the friction force of the thread pair from loosening.

After the two nuts are tightened, the bolt is always subjected to additional axial tension, while the nut is compressed, which increases the friction and deformation between the threads, so as to achieve The purpose of preventing the nut from automatically loosening.

② Mechanical methods to prevent loosening. The mechanical method of anti-loosening refers to the use of various special stop elements to limit the relative rotation of the thread pair. This anti-loosening method is relatively reliable, but it is troublesome to assemble and disassemble. It is suitable for the connection of internal moving components of machinery and occasions with high requirements for anti-loosening.

Commonly used stop elements are: slotted nut and cotter pin (this method is suitable for connections that are subjected to shock loads or increased load changes), stop gaskets to prevent loosening (this method can only be used at the edge of the connected piece connection), lock washers and round nuts to prevent loosening

③ Destroy the anti-loosening of the thread pair. Destruction of the anti-loosening of the threaded pair is a method of preventing loosening of the threaded pair after the threaded pair is tightened to make the threaded pair become a non-threaded pair and become a non-detachable connection. Commonly used methods for destroying thread pairs include punch point anti-loosening method and adhesive anti-loosening method.

④Application range:amusement park、playground、theme park、game center