What Is The Meaning For Shafts Couplings Clutches For Outdoor Amusement Parks Ride Equipment?

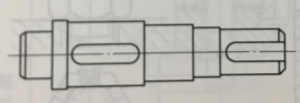

Axis. The shaft is mainly used to support rotating hub parts (such as gears, pulleys, etc.) and transmit motion and power, and it is supported by sliding bearings or rolling bearings. Shaft is one of the indispensable and important parts in mechanical transmission.Depending on the shape of the shaft, the types of shafts are shown in Figure 2-71.

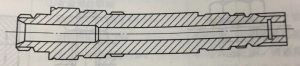

According to different load conditions, the shaft can be divided into three types: rotating shaft, mandrel and transmission shaft. The rotating shaft not only transmits torque but also bears the bending moment, which is the most common in all kinds of machines; the transmission shaft only transmits the torque and does not bear the bending moment or bears a small bending moment, such as the transmission shaft of the automobile; the mandrel only bears the bending moment and Torque is not transmitted. Spindles can be divided into fixed spindles (such as the front axle of a bicycle) and rotating spindles (such as train car axles).

The shaft is mainly composed of three parts: journal, shaft head and shaft body. The supported part on the shaft is called the journal; the part that cooperates with the gear, coupling, etc. is called the shaft head, and the overhanging shaft head is also called the shaft extension; the part connecting the journal and the shaft head is called the shaft body. The part where the section size of the shaft changes is called the shoulder or collar, which is used for the axial positioning and fixing of the parts on the shaft

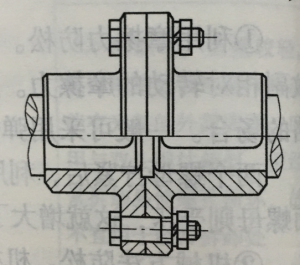

Coupling Coupling is a common component used to connect two shafts to rotate together and transmit motion and torque. The two shafts connected during the rotation cannot be disengaged, and the two shafts can be separated only after the connection is disassembled when the machine is stopped. Couplings are divided into three categories: rigid couplings, flexible couplings and safety couplings.

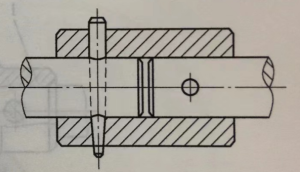

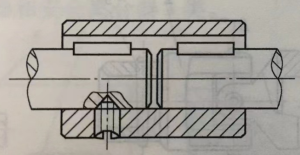

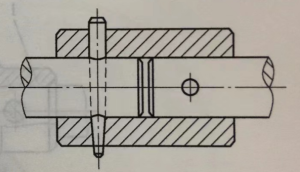

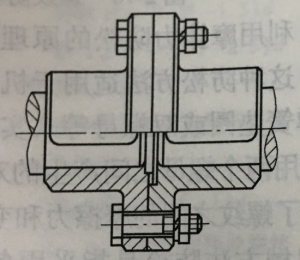

Rigid coupling. Rigid coupling is composed of rigid connecting elements, and the elements cannot move relative to each other, so they do not have the ability to compensate the relative displacement between the two shafts and buffer and reduce vibration. where relative displacement does not occur. Rigid couplings mainly include flange couplings (see Figure 2-72), sleeve couplings (see Figure 2-73) and jacket couplings, among which flange couplings are the most widely used.Application range:amusement park、Family entertainment center、game center、shopping mall.