Parameter

A.Technical standard:

- Safety Code for Amusement Facilities GB8408-2008

- General technical requirements for carousel amusement machines GB/T18158-2008

B. Technical parameters:

- Capacity: 16 seats

- Speed: 3.322r/min=1.74m/s

- Overall height: 4.8 m

- Input voltage: 380V±5% TN-S system

- Power: 3KW drive + 2.5KW decoration

- Occupation: φ7m. The diameter of the top umbrella is 9 meters

- Control: frequency conversion (frequency: 50Hz) speed regulation start and stop

- Total weight of equipment: 10T/floor requires 220kg/square

- Rotation diameter: Φ5.96m

- Power: 380V AC three-phase four-wire 3KW

Horse lifting height: 0.18m

Application range:amusement park、playground、theme park

Working principle

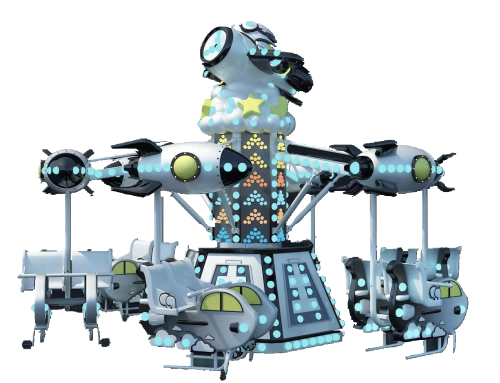

This equipment belongs to the carousel series carousel amusement machine. Its main movement feature is to rotate and lift around the vertical axis. This equipment uses a cylindrical structure as the central column to support the weight of the entire equipment. The turntable used for carrying people is suspended on the canopy composed of cantilevers (trusses) through booms. The canopy is installed on the top of the center column through the center support. The geared motor drive system installed on the center column drives the center support ring gear through gear meshing to drive the roof and the turntable to rotate.

The crankshaft system placed horizontally in the roof is connected with the central column through bevel gear fit. When the canopy and the central column are relatively rotated, under the action of the bevel gear, the crankshaft will move up and down, thereby driving the ride (horse) suspended on the crankshaft to do the lifting movement.

The appearance of this equipment is completely covered with glass fiber reinforced plastic decorations. In order to facilitate maintenance, a maintenance door that can be easily opened is set on the screen glass fiber reinforced plastic in the middle of the turntable, so that maintenance personnel can enter the main body of the equipment easily.

Equipment composition

The whole equipment is divided into two parts, namely the rotating part and the fixed part, but the rotating part and the fixed part are separated by the slewing bearing, and the slewing bearing occupies an important position in the whole equipment. Therefore, during installation and debugging, the slewing bearing must be placed horizontally to make the entire rotating frame stable without swinging and noise. The corresponding slewing bearing must be well lubricated to ensure its service life.

Operation control mode

Operation control has manual and automatic modes,

⑴ The operation process and control of the carousel are: external power supply – system power on – lights and audio on – passengers enter the seat – start – run – end of running time – stop – passengers leave; The next operation; the end of the whole day’s operation – turn off the lights and sound – the operator leaves the operating room – cut off the external power supply.

(2) Steps that require signal detection and control:

①. Before starting, there must be a signal transmission, and the passenger has been in place before the equipment can be started. Otherwise, accidental injury may easily occur.

②. Shut down after the running time is up;

The product is suitable for environmental conditions

Altitude: <2000 meters

Temperature: -5℃~45℃

Humidity: <95%

Wind speed: <15m/s